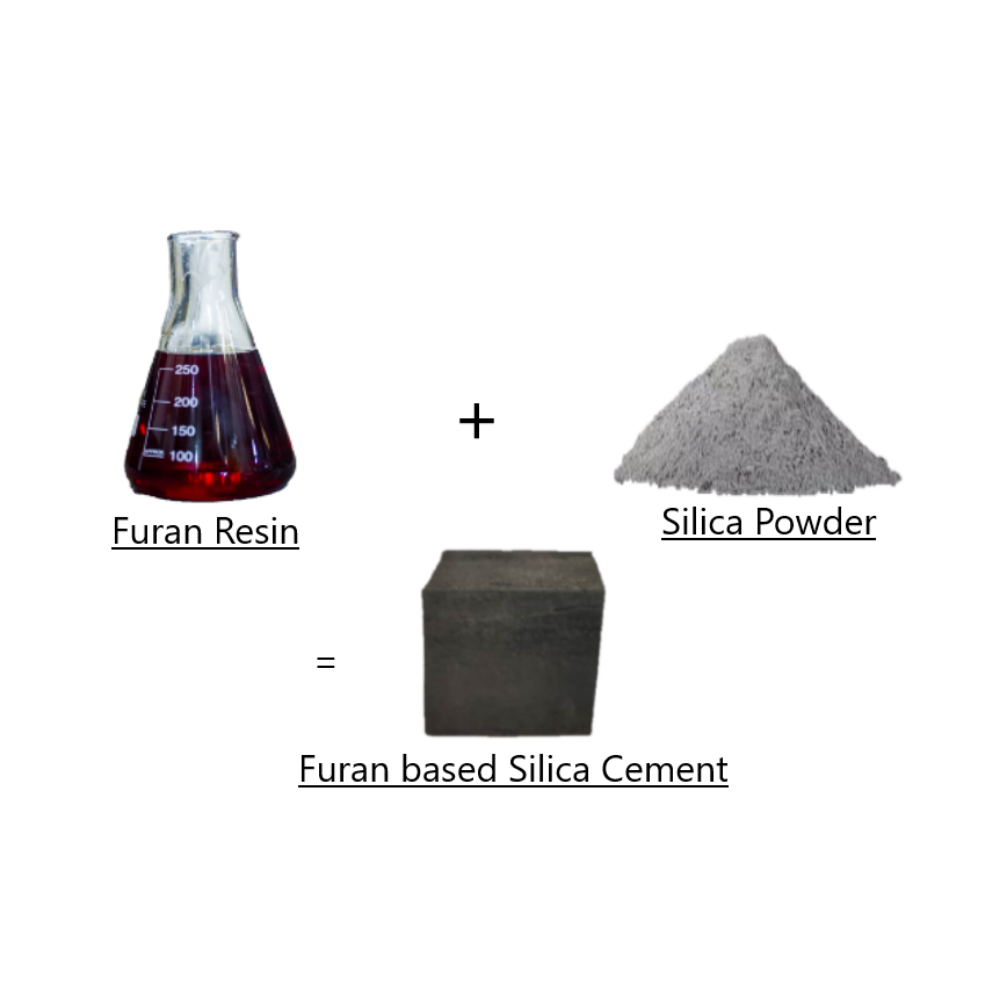

GLOBE FSC MORTAR Furocin Mortar is a specially formulated Furan based Silica Mortar for chemicals resistant bricks construction. Especially for Acid Resistance Bricks bedding, jointing and Pointing Lining in Sulphuric Acid conditions & Anti acid living Mortars

Field Of Application

GLOBE FSC MORTAR (Furocin Mortars) is recommended for Anti Acid Brick lining in Tanks, Floors, Vessels, Receivers, Sumps and Trenches requiring the chemical and physical resistance of brick construction. GLOBE FSC MORTAR is ideal for the chemical processing industries, Sulphuric Acid plant and it is widely used for bedding, Joining and pointing cement of Anti Acid Bricks Lining.

Chemical Resistance

GLOBE FSC MORTAR Furocin Mortar is resistant to organic acid, solvent, oils, greases and salts. It is also resistant to many inorganic acids and alkalis in lower concentrations. GLOBE FSC MORTAR complies with the specifications of ASTM for chemicals resistant furan resin mortars.

Properties

- High chemicals resistance, particularly to acids, alkalies and certain solvents having low concentrations.

- High temperature resistance up to 200°C.

- Long shelf life even at higher temperature. Approx. 24 Months.

- High Mechanical strength.

- Suitable for bedding, Jointing & Painting Mortar for Anti Acid bricks lining.

Available Colours

GLOBE FSC MORTAR is available in black colour only.

Physical & Chemical Properties

| Property | Units | Test Method | Typical Value |

|---|---|---|---|

| Density | gms/cc. | ASTM C905 | 1.60 to 1.70 |

| Bond strength 7 days @(250C) | N/mm2 | ASTM C321 | 1.2 to 1.8 |

| Tensile Strength 7 days @(250C) | N/mm2 | ASTM C307 | 6 to 8 N/mm2 |

| Compressive Strength 7 days @(250C) | APP. N/mm2 | ASTM C579 | app. 50 N/mm2 |

| Flexural Strength 7 days @(250C) | N/mm2 | ASTM C580 | 10 to 12 N/mm2 |

| Coefficient of Thermal Expansion | ASTM C531 | 2.4 x 10-5 (10-5 x K-1) | |

| Water Absorption | ASTM C413 | Less than 1% | |

| Temperature Resistance | - | 200°C Maximum. | |

| Linear Shrinkage | ASTM C321 | 0.5% | |

| Chemical Resistance ( for Phosphoric Acid & Other Acids/Alkalies) | - | Excellent performance Loss of wt. <1% | |

| Working Time | - | 50 to 60 mins. At 27°C | |

| Setting Time | - | 120-180 mins. | |

| Ratio of Powder to Resin (approximately) | - | 2.5:1 |

Mixing Of The Globe FGC Mortar

Mixing of the components should be with mixer with a 5 kg. mortar capacity. The mixing speed should be between 50-60 RPM. Stir the content of the resin container prior to blending. The amount of the poser may be carried slightly to obtain the desired consistency. Proportionally increase or decrease component as per batch size requirement. Mixing of material may be possible manually into the metal pot container as per required quantity to be used for lining purpose. A thick black gravy solution will be recommended for lining with ratio 1:1 (Powder to liquid) approximately.

Consumption

Bedding and jointing (Bedding 5-7mm / jointing 2-3 mm)

| Material | Dimensions | Consumption |

|---|---|---|

| Tiles | 230x115x12 | Apprx. 12 kg. /m2 |

| Tiles | 230x115x20 | Apprx. 14 kg. /m2 |

| Tiles | 230x115x25 | Apprx. 16 kg. /m2 |

| Bricks | 230x115x40 | Apprx. 18 kg. /m2 |

| Bricks | 230x115x40 | Apprx. 21 kg. /m2 |

| Bricks | 230x115x65 | Apprx. 22 kg. /m2 |

| Bricks | 230x115x75 | Apprx. 23 kg. /m2 |

| Bricks | 230x115x80 | Apprx. 25 kg. /m2 |

| Bricks | 230x115x100 | Apprx. 27 kg. /m2 |

Storage & Shelf Life

The resin & mortar should be kept in cool & dry place tightly closed, away from moisture, heat & direct sunlight. For safety reasons keep both resin & powder away from each other. All three materials have a shelf life of min. 12 months as recommended conditions. In case the ambient Temp. is more than 30-35o C, the shelf life of above materials will get reduced accordingly.

Health & Safety

Adequate ventilation is to be provided while work is in progress. Ventilation is compulsory for all work carried out in pits and closed rooms. All vapours that are produced while work is in progress must be continuously suctioned off at floor or bottom level. Mostly the mixing of mortar is to be carried out at open surface. Only the amount of material effectively required to continue work is to be stored at working place the instruction for the prevention of fire and explosion are to be observed, if required. Please note and ensure that even the smallest quantities of the individual components and/or pre-pared mixtures are not allowed to reach the sewerage. All regulation for the prevention of accidents prescribed at the site of application & surface treatment in rooms and tanks, as well as the safety precautions listed on the packing (label) required by the provisions of the Hazardous Materials ordinance shall be adhered.